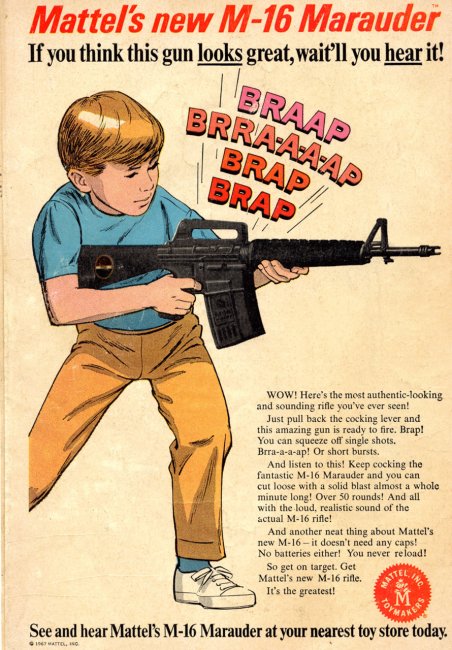

I'll add to this thread as I progress with my "Mattel M16A1" (semi-auto) build. My goal is to end up with an AR that looks like what a Vietnam era Mattel M16A1 (that never existed) would have looked like. To that end, I'll need to find M16A1 looking parts if I can afford them. Got a line on a Colt bbl and triangular hand guards and have started looking for pistol grip and buttstock on the Internet.

I suppose since a Mattel never existed, that might give me a little freedom in the build and to "make up" Mattel facts as needed. For example, a vintage upper might be lighter in shade than my new anodized dark lower...but then Mattel only made the lowers and used other contractor's uppers in the early part of their short lived contract to make M16A1's.

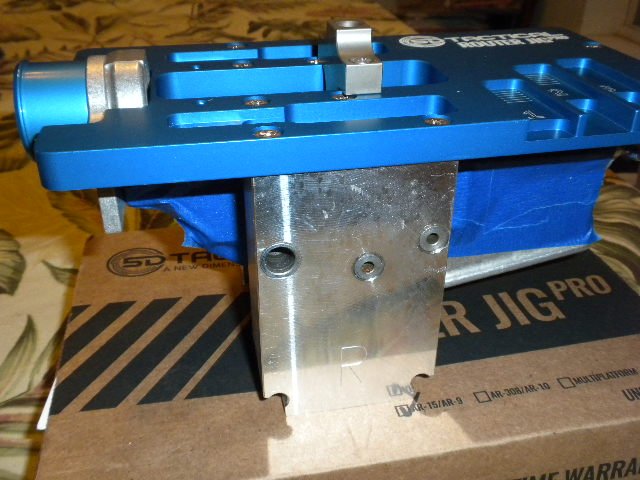

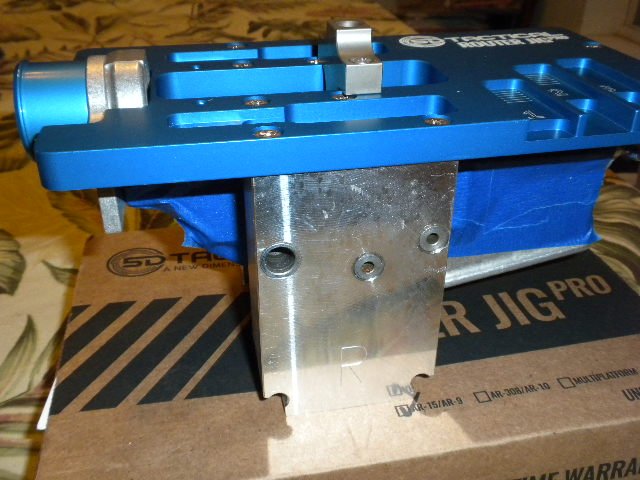

My "Mattel" 80% lower arrived today along with a 5D Tactical jig and tool set. I'm having dinner with my son-in-law this evening, and we'll discuss the next step. I'm using his workshop, router, and drill. A friend gave me a plain 80% lower to practice on and a vise to hold the lower during the milling and drilling.

The lettering looks sharper in person. I'm thinking of filling in the lettering with aluminum black since I'll be blackening the inside after milling and drilling.

I suppose since a Mattel never existed, that might give me a little freedom in the build and to "make up" Mattel facts as needed. For example, a vintage upper might be lighter in shade than my new anodized dark lower...but then Mattel only made the lowers and used other contractor's uppers in the early part of their short lived contract to make M16A1's.

My "Mattel" 80% lower arrived today along with a 5D Tactical jig and tool set. I'm having dinner with my son-in-law this evening, and we'll discuss the next step. I'm using his workshop, router, and drill. A friend gave me a plain 80% lower to practice on and a vise to hold the lower during the milling and drilling.

The lettering looks sharper in person. I'm thinking of filling in the lettering with aluminum black since I'll be blackening the inside after milling and drilling.